ナカヤのチラー開発について

弊社温調機器事業部は、温調機器の設計/開発を行うエンジニアリングを行っており、

生産は、生産を専門に行っている企業に委託をしています。

台湾、韓国、中国においても同じです。

大手装置メーカーからの開発依頼を受け、二元冷凍機ユニット搭載のチラーを開発しました。

ここでは、弊社オリジナルのチラーをご紹介します。

ナカヤ製チラーの3つの特徴

ナカヤオリジナル インターネットチラー(IOTチラー) (特許出願中)

インターネットチラー、IOTチラーは商標登録済み

DCインバータコンプレッサーや電子膨張弁の動作をパラメータ化して管理をしているので、

インターネットを介してチラーにアクセスする事で、遠隔でのパラメータの再調整管理が可能

もう、現場に行かずに故障診断や再調整が可能になります。

特許取得!省エネルギーを可能にした、エリア別パラメータ制御方式のハイブリッドチラー(特許第5762493号)

DCインバータコンプレッサーによる、負荷に適した冷媒循環量の管理

電子膨張弁による、設定温度に適した冷媒蒸発温度の管理

冷媒循環量と冷凍効果を各設定温度に応じてパラメータ管理する事で、 単にホットガスによる省エネよりも一歩進んだ省エネを実現

国内・海外専門企業と提携、生産と品質を管理

チラーの生産や品質管理は専門企業に委託(弊社はエンジニアリングに特化しています) 海外生産も同様で、台湾、韓国、中国の協力企業に生産を委託 受託設計/開発も可能です。

インターネットチラーのご紹介

VPNルーター等を使用すれば、インターネット経由でチラーにアクセスをする事が出来ます。

チラーはDCインバータコンプレッサーや電子膨張弁を使用していますので、仮に不具合が発生しても、遠隔操作により再調整が出来るのでわざわざ現場に行く必要はありません。

WIFI対応のVPNルーターであれば、社内ネットワークを経由する事もありません。必要な時だけインターネットに接続をするだけ、セキュリティの面でも安心です。

チラーには運転状態のログデータが残る様になっており、そのログデータはチラーにアクセスしているPCにドラッグ&ドロップで取込む事が出来ます。定期的にログを確認する事で、不具合を未然に防ぐ事も可能です。

チラーの定期メンテナンス契約を結んで頂ければ、定期的にチラーの状態を確認し、ご報告を行う事が可能です。

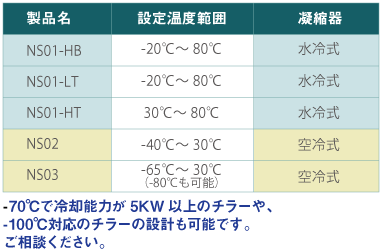

チラー製品別 商品詳細ページ